ProTuBar

Key Features of the Tube Drawing Software

- Management of technical and scientific key data by a user friendly

XP, Vista and 7 compatible software (Workstations/LAN/WAN) in order to

allow the planning of advanced tube production based on the latest

software technology

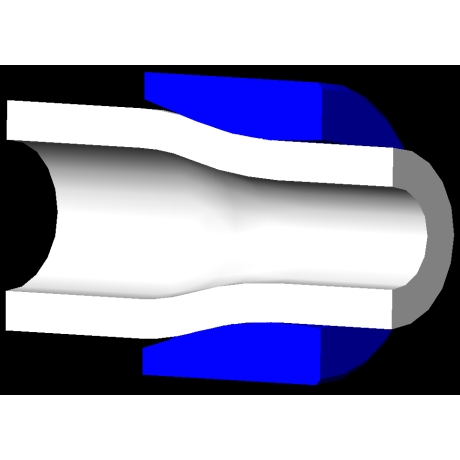

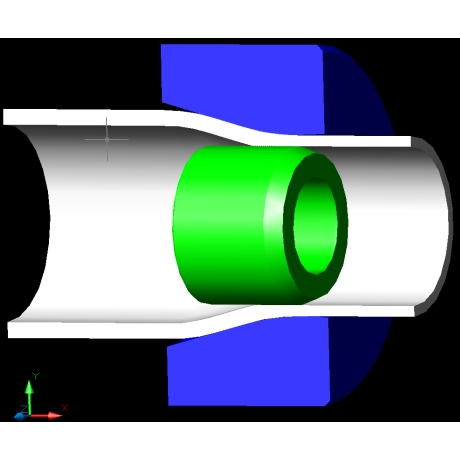

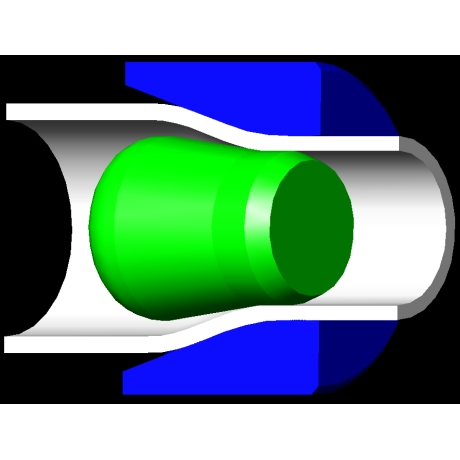

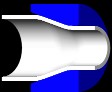

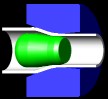

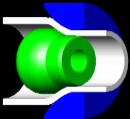

- Three dimensional simulation of the tube drawing system

- Integrated production planning module including automatically generated and dimensioned tool drawings

- Integrated production control and tool management modules

- Highly beneficial system for the technical sales staff as well

- Database allows the evaluation of production outcome and statistical analysis in order to continuously improve the production parameters and the systematical generation of independent key knowledge at the tube plant

- Calculation of a large number of important drawing parameters like reductions, drawing force / stress, change of mechanical properties due to cold forming, temperatures, drawing angles, etc.

ProTuBar contains a CAD interface that displays the drawing process and the tool

design within the AutoCAD environment. The following cold drawing

processes are integrated:

- Sinking

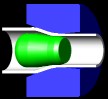

- Stationary plug

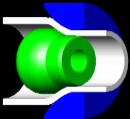

- Moving mandrel

- Floating plug (including sphere-shaped shoulder)

- Proprietary tube drawing processes like divided plug / die

- Bar / rod drawing

ProTuBar features a unique material model, which enables the estimation of the

flow curve through common mechanical properties of the pre material.

This common material data is generally easily available even for unusual

alloys or can alternatively be obtained by a simple tension test.

These distinctive features make ProTuBar the ideal contribution to the competitiveness of every cold drawing production.

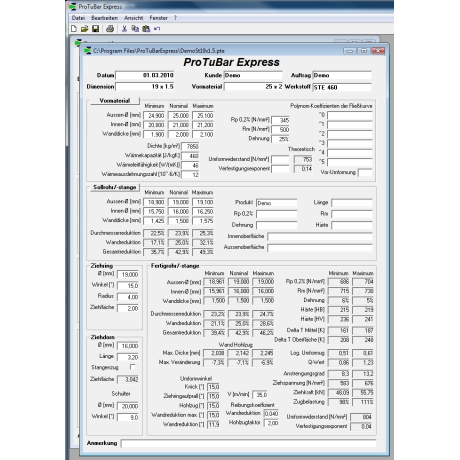

ProTuBar Express

ProTuBar express is based on the original ProTuBar concept and features the same computations at a lower license fee.

The Express version works with a multiple document user interface

and files instead of the relational database of the original program and

it does not contain a CAD-interface. These simplifications make ProTuBar Express very easy and straightforward to use even without

dedicated training.

A large number of important drawing parameters like reductions, drawing force / stress,

change of mechanical properties due to cold forming, temperatures,

drawing angles, etc. are automatically and immediately calculated.

The following cold drawing processes are integrated:

- Sinking

- Stationary plug

- Moving mandrel

- Floating plug (including sphere-shaped shoulder)

- Proprietary tube drawing processes like divided plug / die

- Bar / rod drawing

The Express version features the same unique material model of the full version,

which enables the estimation of the flow curve through common

mechanical properties of the pre material. This common material data

is generally easily available even for unusual alloys or can

alternatively be obtained by a simple tension test.

These distinctive features make ProTuBar Express a vital and easily affordable contribution to the competitiveness of every cold drawing production.